|

Beverage flow meter With RS485

|

| Size£ºDN3-DN3000 |

| Electrode:SS316,HC,HB,Ti,Tan,Pt |

| Liner Material: PTFE,PFA,FEP,NEOPRENE,HARD RUBBER |

| Accurance: 0.5% of reading velue,0.3% and 0.2% optional |

| Connection: Flange,Tri-clamp,Wafer,Union |

| output:4-20mA/pulse, communication:RS485,HART,GPRS |

| |

|

Introduction

Beverage flow meter works based on Faraday¡¯s Law and measure conductive medium with conductive medium with conductivity more than 5¦Ìs/cm and flow range from 0.2 to 15m/s

Features:

- No moving parts, no pressure loss

- Accuracy :0.5% of the measured value

- High accuracy for low flow rate and can measure duplex flow

- Double frequency excitation ,stable zero point

- Built-in ground electrode ,no need grounding ring

Application

- Chemical

- Medicine

- Beverage

- Iron and steel

- Water supply

- Electricpower

- Water treatment

|

|

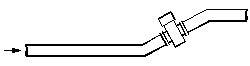

Beverage flow meter |

connection way: tri-clamp |

|

|

liner material: PTFE |

Production Process

|

Converter Selection Model

|

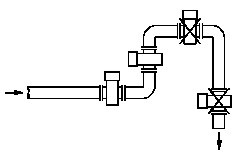

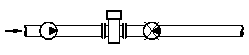

Installation

shoud be installed at the rising pip shoud be installed at the rising pip

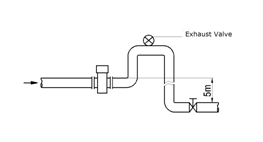

For installing at open pipe, Flowmeter should be installed at relative low. If pipe fall is more than 5m, vent valve should be installed at sensor downstream where should have backpressure. For installing at open pipe, Flowmeter should be installed at relative low. If pipe fall is more than 5m, vent valve should be installed at sensor downstream where should have backpressure.

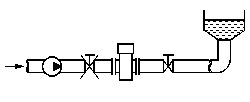

Control valve and stop valve shall be installed at downstream of sensor not upstream. Control valve and stop valve shall be installed at downstream of sensor not upstream.

Sensor shall be installed at outlet of pump not inlet. Sensor shall be installed at outlet of pump not inlet.

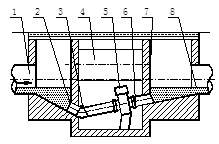

Installation way in measure well: Installation way in measure well:

1. Inlet; 2.Entrance gate; 3. Cleaning hole; 4.Overflow pipe; 5.Flow Meter; 6.Nozzle stub; 7.Outlet; 8.Drain valve.

|

Project Case

|

1 2 |

|